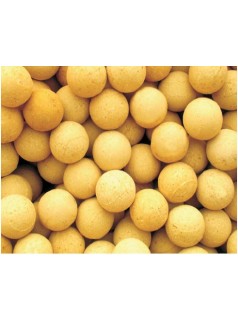

耐火球

Refractory Ball

耐火瓷球耐火球是以工业氧化铝和耐火高岭土为主要原料,经科学配方、成形和高温煅烧制成的。它具有:

1. 机械强度高,使用周期长;

2. 化学稳定性好,不与物料发生化学反应;

3. 耐高温性能好,耐火瓷球高耐热温度可达到 1700 度。

特别适用于化肥厂高低温变换炉、转化炉、加氢转化器、脱硫槽及甲烷化炉中,起分散气液、并支撑、覆盖和保护催化剂的作用。耐火瓷球也可用于钢铁行业的热风炉和加热变换设备中。

Refractory Ball is mainly composed of industrial alumina and kaolin, manufactured through science recipe, molding and high-temperature calcinations. It features:

1. High mechanical strength, long life cycle;

2. Chemically stable, not reacting with the material;

3. Temperature-resistant performance, maximum temperature is allowed to be 1,700 Celsius degree.

Refractory ball is especially fit for furnace in fertilizer plant in terms of high & low temperature conversion, hydrogenation conversion equipment, desulfurization and methanation furnace tank. It works with the performance of scattering from the gas & liquid, also supporting, covering and protecting the catalyst. It can also be used for the steel industry in the hot-blast stove and heat conversion device.

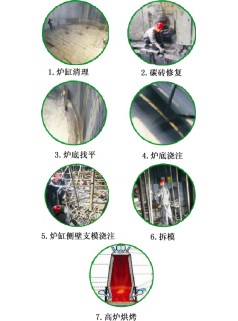

热风炉换球方案

1安全培训 2工具准备 3 凉炉 4卸球 5更换炉箅子 6装球 7点火烘炉 8 炉况运行

The Plan of Replacing Refractory Balls in Hote Stove

1.Safety Training

2.Tools Preparation

3.Cooling Hot Stove

4.Remove the used inoperative ball

5.Changing Stove Grate

6.Ball loading

7.Igniting Stove

8.Running

1.HX高强高铝耐火球

High-strength high-alumina refractory ball

我公司是国内早生产耐火球的少数专家之一,在耐火球更新换代方面适中潮流,其中HX系列高强高铝耐火球、高强低蠕变高铝耐火球、微粉结合“三高”耐火球、微粉结合刚玉耐火球,是我公司历经五年潜心研究的专利产品。经昆钢、酒钢、柳钢、大冶特钢等厂家使用,效果非常理想,赢得用户赞誉。

Our company is the earlier one of several factories only to produce refractory balls. It always occupies the frist place to replace with new generation of refractory balls, including HX system of high-strength high-alumina ball, high-strength low-creep high-alumina ball, micro-powder bounded “3-high” refractory ball, micro-powder bounded corundum ball, which are patent products researched by us with great concentration for 5 years. They were efficiently used in iron and steel factory in China,such as Kunming steel , Jiuquan Steel, Liuzhou steel, Daye steel,etc., and wined good praise from customers.

|

牌号Brand |

HXGG |

|

Al2O3 (%) |

65—70 |

|

Fe2O3 (%) ≤ |

1.5 |

|

耐火度(℃)≥ Refractoriness |

1790 |

|

显气孔率(%) ≤ Apparent porosity |

23 |

|

体积密度( g/cm3 )≥ Bulk density |

2.35—2.5 |

|

常温耐压强度(N/球)≥ Cold crushing strength (N/ball) |

11000—19000 |

|

重烧线变化率(%) [1450℃×2h] Linear change after heating(%) [1450℃×2h] |

0—0.3 |

|

荷重软化开始温度(℃) ≥ Refractoriness under load |

1480 |

|

热震稳定性(次)[1100℃-水冷] ≥ Thermal shock resistance,(times)[1100℃ water-cooling] |

18 |

|

用途 Application |

球式热风炉 Ball-type hot stove |

*备注:此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定

Remark:This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements.

2. HX High-strength low-creep high-alumina ball

HX高强低蠕高铝耐火球

该产品是在高强度高铝耐火球基础上研制的第二代产品。主要特点:抗高温蠕变性能优良,其使用寿命达到一代高炉大修周期,可提高热风炉风温到1100℃以上,节省煤气消耗,节能效果显著。

This product is the second generation based on the frist refractory ball, having the advantages of good hot creep property. Its service life is as long as one campaign of blast furnace heavy repair. It can increase the wind temperature of hot stove more than 1100℃, efficiently saving coal gas. The energy saving is excellent.

|

牌号Brand |

HXGD-65 |

|

Al2O3 (%)≥ |

65 |

|

Fe2O3 (%) ≤ |

1.5 |

|

耐火度(℃)≥ Refractoriness |

1790 |

|

显气孔率(%) ≤ Apparent porosity |

23 |

|

体积密度( g/cm3 )≥ Bulk density |

2.5—2.6 |

|

常温耐压强度(N/球)≥ Cold crushing strength (N/ball) |

23000 |

|

重烧线变化率(%) [1450℃×2h] Linear change after heating[1450℃×2h] |

0—0.2 |

|

荷重软化开始温度(℃) ≥ Refractoriness under load |

1550 |

|

高温蠕变率(℃)[0.2MPa×1400℃×5h] ≤ Hot creep rate |

0.5 |

|

热震稳定性(次)[1100℃-水冷]≥ Thermal shock resistance, ( times)[1100℃ water-cooling] |

20 |

|

用途 Application |

球式热风炉 Ball-type hot stove |

*备注:此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定

Remark:This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements.

3.HX Micro-power bonded “3-high”refractory ball ( patented product )

HX微粉结合“三高”耐火球(专利产品)

该产品是我公司的第三代耐火球产品,由于引入了微粉技术,使得耐火球的高温性能进一步提高,其寿命与高炉基本同步,并能提高风温到1200℃以上,节能效果显著,是当今球式热风炉产品。

HXSG65 refractory ball is the third generation refractory ball. Because the micro-powder technology is introduced, its hot property is higher. The service life is as long as blast furnace campaign. It increases the wind temperature to more than 1200℃. The energy saving is excellent. At present time it is the first choice for ball-type hot stove.

|

牌号Brand |

HXSG-65 |

|

Al2O3 (%) |

65—70 |

|

Fe2O3 (%) ≤ |

1.5 |

|

耐火度(℃)≥ Refractoriness |

1790 |

|

显气孔率(%) ≤ Apparent porosity |

22 |

|

体积密度( g/cm3 )≥ Bulk density |

2.6 |

|

常温耐压强度(N/球)≥ Cold crushing strength (N/ball) |

25000 |

|

重烧线变化率(%) [1450℃×2h] Linear change after heating(%) [1450℃×2h] |

0—0.2 |

|

荷重软化开始温度 (℃) ≥ Refractoriness under load |

1550 |

|

高温蠕变率%[0.2MPa×1400℃×5h] ≤ Hot creep rate |

0.3 |

|

热导率(W/m?K)1100℃ ≥ Thermal conductivity |

0.4 |

|

热震稳定性(次)[1100℃-水冷]≥ Thermal shock resistance, ( times)[1100℃ water-cooling] |

24 |

|

用途 Application |

球式热风炉 Ball-type hot stove |

*备注:此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定

Remark:This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements.

4.HX micro-power bonded corundum ball ( patented product )

HX 微粉结合刚玉耐火球

该产品是我公司的第四代耐火球产品近年来我公司用纳米技术开发出微粉结合刚玉耐火球,能提高风温到1250℃以上,使用寿命可满足高炉一代炉龄,且可以反复使用,节能效果显著,是当今球式热风炉佳产品。

This products is the fourth generation of refractory ball. In recent years we have produced the ball introducing nanometer technology, increasing wind temperature more than 1250℃. The service life is as long as one campaign of blast furnace. It can be used second time. Energy saving is excellent. At present time it is the first choice for ball-type hot stove.

|

牌号Brand |

HXGD-80 |

|

Al2O3 (%)≥ |

80 |

|

Fe2O3 (%) ≤ |

1.5 |

|

耐火度(℃)≥ Refractoriness |

1790 |

|

显气孔率 (%) ≤ Apparent porosity |

19 |

|

体积密度( g/cm3 )≥ Bulk density |

2.8 |

|

常温耐压强度(N/球) Cold crushing strength (N/ball) |

40000 |

|

重烧线变化率(%) [1450℃×2h] Linear change after heating |

0—0.2 |

|

荷重软化开始温度(℃) ≥ Refractoriness under load |

1580 |

|

高温蠕变率(℃)[0.2MPa×1400℃×5h] ≤ Hot creep rate |

0.2 |

|

热导率(W/m?K)1100℃≥ Thermal conductivity |

0.6 |

|

热震稳定性(次)[1100℃-水冷]≥ Thermal shock resistance, ( times)[1100℃ water-cooling] |

26 |

|

用途 Application |

球式热风炉 Ball-type hot stove |

*备注:此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定

Remark:This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements.

6、 纳米远红外增热制膜技术

Nano far-infrared heating film technology

纳米远红外增热制膜技术是指利用纳米微粉形成的小颗粒通过高温反应胶结到耐火球的表面,使得耐火球表面形成一层具有吸收热能很大的膜层,纳米粉的颗粒直径和远红外线的波长相接近,能够更好地吸收物体辐射的热能,终达到热交换的目的,所以我们给这种新技术定义为纳米远红外增热制膜技术。

It is by using granulum from nano-powder,which is cemented to the surface of refractory ball through high-temperature reaction. And the surface of refractory ball will from a film with function of high heat absorption. The diameter of nano particle is close to the wavelength of far infrared ray, so it can better absorb heat of radiation and finally achieve the aim of heat exchange.

纳米远红外制膜技术,主要在改善耐火球的体积密度和降低气孔率上,在热交换的循环过程中,单位时间内的蓄热和放热的能力都得到了提高,热传导的热效率也相应提高。等于说燃烧时间内,耐火球吸收的热量和吸热的速度增加了,送风时期耐火球的放热量和放热速度也增加了,从而达到热交换效率的提高,相同时期内废气的温度降低了。单位时间内耐火球的蓄放热的量增加,能够使热风温度提高。高炉的冶炼强度提高了。

It is mainly used to improve the bulk density and porosity of refractory ball. In the heat exchange circulation process, the capacity of heat storage and heat release are improved in unit time. And the heat conductivity is also improved. As the capacity of heat storage and release are improved, the hot blast temperature is increased, which improves the smelting intensity for blast furnace.

制膜和不制膜对比试验:

Contrast Text:

|

项目 Item |

体积密度 Bulk density |

气孔率 Porosity |

耐压强度 Crushing strength |

荷重软化 Refractoriness under load |

高温蠕变 High temperature creep |

热震稳定 Thermal shock stability |

|

|

g/cm3 |

% |

N/球ball |

℃ |

% |

次time |

|

有涂膜 Coating film |

2.63 |

20.4 |

27400 |

1537 |

-0.27 |

25 |

|

无涂膜 No film |

2.54 |

22.3 |

14100 |

1503 |

-0.43 |

21 |

通过在日照钢铁厂、萍乡钢铁厂、山东石横钢铁厂等多家厂家的试用和验证:有制膜技术相对无制膜耐火球的热风炉,燃烧期吸热快,蓄热量增加;放热期内放热快,热风出口温度高约18-25℃;烟气出口温度约低10-15℃。从而达到提高风温,增强冶炼强度并且达到节能的目的.

With verification test in several steel plants, the hot blast stove with refractory ball of coating film can absorb heat quickly and increase the hest storage. Moreover it can raise the hot blast temperature and strengthen the smelting intensity, which accomplish the aim of energy conservation.

粤公网安备 44030702001206号

粤公网安备 44030702001206号