高炉整体维修一体化解决方案

Integrated Maintenance Solution of Blast Furnace

1.整体炉缸浇筑 Overall Casting Technology of Blast Furnace

2.高炉湿法喷涂造衬 Wet Spraying Technology for Making Lining of Furnace

修复类型

Repair Type:

一、 高炉内衬修复与再造

Blast Furnace lining Repair and Reconstruction

1.高炉人工、自动化喷涂与喷注 Manual spraying and automatic spraying

2.高炉气密箱 Gas seal box of blast furnace

3.局部可以特殊修补 Special repair for partial area

4.炉缸整体无缝浇注 Overall casting technology of furnace hearth

二、热风炉

Hot Blast Stove

1.热风炉整体喷注 Overall spraying of hot blast stove

2.热风管道系统 Hot air pipeline system

3.热风炉烟道 Hot blast stove flue

三、管道喷注

Pipeline Spraying

1.荒煤气管道 Coke-oven gas pipeline

2.半净煤气管道 Semi purified gas pipeline

3.烧结机烟道 Sintering machine flue

4.除尘管道 Dust extraction tube

四、其他喷注

Spraying for Other Area

1.出铁厂平台底部 Cast house platform bottom

2.粗煤气系统 Crude gas system

3.竖炉炉内 Shaft furnace inside

一、炉缸整体无缝浇注技术

Overall Seamless Casting Technology of Furnace Heart

高炉炉缸整体浇注是一项重建陶瓷杯的新技术,其特点在于紧贴炭砖直接进行支模浇筑,浇注的陶瓷杯与炭砖紧密结合,致使炉缸结构更加紧密。不存在传统陶瓷杯与炭砖间的填充层,减少了热阻层,使浇注炉缸整体传热效率得到保证,达到传热平衡,保护内衬安全,避免多种隐患等问题的发生。

It is a new technology of re-building ceramic cup, which is characterized by setting up mold and casting cling to carbon brick. The casting ceramic cup and carbon bricks will be seamless connectivity, which makes the structure of furnace heart compactly and tightly. And there is no filling layer between traditional ceramic cup and carbon bricks, which cut down thermal resistance layer, guarantee the overall heat conducting efficiency, protect the safety of furnace liner and avoid the occurrence of potential risk.

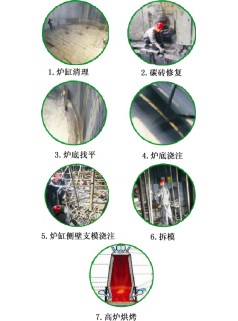

1.炉缸浇注流程 Procedure

炉缸清理Clean up the hearth 炭砖修复 Repair of carbon brick 炉底找平 Make level in the hearth bottom 炉缸侧壁支模浇注 Casting of hearth bottom 拆模 Set up mold and casting inside wall of breath 高炉烘烤 Form removal Baking

2. 炉缸浇注用料 Casting Technology of Blast Hearth

(1)HX高炉用炉缸浇注料

Overall Casting Technology of Furnace Hearth

|

项目 |

HX-XSR |

||

|

Al2O3( %) |

75 |

||

|

CaO (%) |

0.5 |

||

|

Fe2O3 (%) |

1 |

||

|

SiC (%) |

13 |

||

|

抗折强度(M pa) Bending strength |

1450℃×3h |

12 |

|

|

耐压强度(M pa) Crushing strength |

1450℃×3h |

70 |

|

|

线变化率(%) Linear change |

1450℃×3h |

0.1--0.8 |

|

|

体积密度(g/cm3) Bulk density |

110℃×24h |

2.95 |

|

|

使用部位 Application area |

高炉炉缸、风口带 Furnace hearth, tuyere zone |

||

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定. This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

||

(2)HX高导热浇注料

High Thermal Conductivity Castable

|

项目 |

HX-XSR |

||

|

Al2O3( %) |

|

8 |

|

|

SiC (%) |

|

74 |

|

|

耐压强度(M pa) Crushing strength |

1450℃×3h |

69 |

|

|

体积密度(g/cm3) Bulk density |

1450℃×3h |

0.5 |

|

|

线变化率(%) Linear change |

110℃×24h |

2.4 |

|

|

热导系数(W/m.k) Thermal conductivity |

600℃ |

1.2 |

|

|

使用部位 Application area |

修补炭砖 Carbon brick |

||

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定. This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

||

3.炉缸浇注施工现场 Construction Site

二、遥控热态湿法喷注技术

Remove Control Hot Wet Spraying Technology

遥控热态湿法喷注技术是用湿法喷注机先将变为浇注料加水后预搅拌均匀的砂浆状,然后与热态遥控喷注机械手相配合,通过遥控操作,使泵送的浇注料在喷枪口处与雾化的速凝剂混合喷出,瞬时在高炉炉体表面凝固。

Remove control hot wet spraying technology is a new technology, which pours material into blender of wet spraying machine, adding water to mix them evenly. Then coordinating with remote control hot spraying manipulator, adjusting rotation angle and direction, the mixed material is pushed to the head of spraying gun with accelerating agent, the castable will spread out through the surface of blast furnace lining and coagulate instantly.

1.高炉内衬喷涂(喷注)程序

Blast Furnace Lining Gunning Procedure

准备机器Prepare machine 控制炉温<110℃和煤气浓度<50ppm Control furnace temperature (<110℃)and gas (<50ppm) 清洗炉墙和冷却壁 Clean furnace wall and cooling stave 搅拌喷注料 Blending material 机械调整喷注厚度和高度 Adjust spraying thickness and height by machine

用机械手喷注

Manipulator spraying

2.高炉喷注施工现场Construction Site

3.喷注用料 Physical and Chemical Specification

(1)HX长寿型高新热态陶瓷喷注料

HX Longevity high-tech hot ceramic gunning mix

华西长寿型高新热态陶瓷喷注料是由我集团公司专家团队经过潜心研究,在原来喷补料的基础上,研制出的一种新型耐火材料,得到了国内外钢铁企业的认可,远销海外。

HX longevity high-tech hot ceramic gunning mix is developed by the research and test of our technical team based on original gunning mix and won wide recognition from iron & steel plants both at home and abroad.

|

项目 Item |

单位Unit |

喷注料-1 Gunning-1 |

喷注料-2 Gunning-2 |

|

Al2O3 |

% |

≥ 60 |

≥ 58 |

|

SiC |

% |

- - |

≥ 10 |

|

CaO |

% |

≤ 4.2 |

≤ 2.9 |

|

体积密度 Bulk density |

g/cm3 |

≤ 2.3 |

≥ 2.4 |

|

耐压强度110℃ Crushing strength |

M.Pa |

≥ 25 |

≥ 30 |

|

耐压强度1400℃ Crushing strength |

M.Pa |

≥ 45 |

≥ 50 |

|

线变化率 Linear change |

% |

1300℃ ± 0.5 |

1400℃ ± 0.5 |

|

使用部位 Application |

炉身中上部 Middle and upper part of furnace shaft |

炉身下部、炉腰炉腹 Lower part of furnace shaft, belly and bosh |

|

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定 This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

||

(2)净煤气系统喷涂料FH—140理化性能

Physical and Chemical Properties of Purified Gas System Gunning Mix FH-140

|

项目 Item |

单位 Unit |

指标 Index |

|

|

Al2O3 |

% |

45 |

|

|

抗折强度 Bending strength |

110℃×24h |

M.Pa |

5.88 |

|

1400℃热态 Thermal state |

0.98 |

||

|

线变化率 Linear change |

% |

1.0 |

|

|

体积密度 Bulk density |

g/cm3 |

1.8 |

|

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定 This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

||

(3) HX高炉用各种喷涂料

HX Hot Blast Stove Used Gunning Mix

|

项目 Item |

单位 Unit |

GWP-35 |

GWP-45 |

GWP-55 |

|

|

化学成分 Chem.comp |

Al2O3 |

% |

≥35 |

≥45 |

≥55 |

|

Fe2O3 |

% |

≤1.5 |

≤.5 |

≤1 |

|

|

体积密度 Bulk density |

110℃×24h |

g/cm3 |

≥2.0 |

≥2.1 |

≥2.4 |

|

耐压强度 Crushing strength |

110℃×24h |

M.Pa |

≥30 |

≥35 |

≥35 |

|

1000℃×3h |

M.Pa |

≥25 |

≥30 |

≥30 |

|

|

热处理温度×3h Heat treatment temperature |

M.Pa |

≥45 1200℃ |

≥50 1400℃ |

≥55 1500℃ |

|

|

线变化率 Linear change |

1000℃×3h |

% |

±0.5 |

±0.5 |

±0.5 |

|

热处理温度×3h Heat treatment temperature |

% |

±1.0 1200℃ |

±1.0 1400℃ |

±1.0 1500℃ |

|

|

耐火度 Refractoriness |

|

℃ |

≥1530℃ |

≥1650℃ |

≥1670℃ |

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定 This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

||||

(4)HX热风炉用各种喷涂料

HX Hot Blast Stove Used Gunning Mix

华西公司结合自身特点,引进日本先进的喷涂技术,所生产的喷涂料具有产品性能稳定,回弹率低、强度大、收缩小、施工性能好等特点。并配有专业施工队伍及施工技术指导,确保材料和施工质量,用户非常满意。

The hot blast stove used gunning mix is developed by combining our own characteristics and Japanese advantage gunning technology. It is with stable performance, low rebounded elasticity, high strength, low shrink, good construction performance and etc..

|

项目 Item |

单位Unit |

喷涂料Gunning Mix |

||||||

|

FL-130 |

GL-130G |

FN-130 |

FN-140 |

HX-耐酸 Acid resistance |

||||

|

化学成分Chem.comp |

Al2O3 |

% |

≥35 |

≥45 |

≥40 |

≥45 |

≥50 |

|

|

耐火度Refractoriness |

℃ |

—— |

—— |

≥1530 |

≥1590 |

≥1530 |

||

|

体积密度Bulk density |

g/cm3 |

≥1.4 |

≥1.4 |

≥1.65 |

≥1.8 |

≥1.8 |

||

|

抗折强度 Bending strength |

110℃×24h |

M.Pa |

≥3 |

≥3 |

≥2 |

≥3 |

≥3 |

|

|

烧后× 3h After burning |

M.Pa |

1300℃ ≥0.4 |

1300℃ ≥0.5 |

1300℃ ≥4 |

1400℃ ≥4.5 |

浸酸后 After pickling ≥4.5 |

||

|

导热系数 Thermal conductivity |

350℃ |

W/m.k |

≤ 0.35 |

≤ 0.35 |

≤ 0.75 |

-—— |

—— |

|

|

线变化率 Linear change |

3h |

% |

1300℃ ±1.0 |

1300℃ ±1.0 |

1300℃ ±1.0 |

1400℃ ±1.0 |

1300℃ ±1.0 |

|

|

特性 Characteristics |

回弹率低、强度大、收缩小、施工性能好 Low rebounded elasticity, high strength, low shrink, good construction performance |

|||||||

|

使用部位 Application Area |

用于高炉、热风炉的本体内衬,高炉炉喉、炉顶及煤气导出系统、热风炉炉顶、热风管道系统,煤烟、烟囱系统的保护层和炉衬的喷涂施工。 Blast furnace and hot blast stove body lining, furnace throat, furnace top and gas delivery system, hot blast stove top, hot blast pipeline system, protective layer of soft coal and chimney and gunning construction of blast lining. |

|||||||

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定。 This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

|||||||

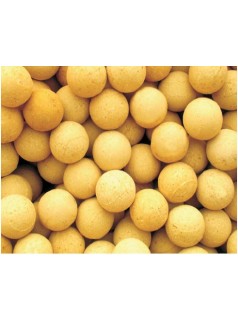

(5)HX高强隔热纤维复合喷射料(公司专利产品)

HX High-strength Compound Insulating Fiber Gunning Mi

(Patent Products)

早在2006年,公司就研发了HX高强隔热纤维复合喷射料(专利号200610017726.1)改善了喷涂料的隔热性能,有效降低了热损失,防止炉壳过热,提高热风温度。使用时配上相应的的化学粘结剂采用高压喷射施工方式,将加工过有强度的球状纤维绒、粘结剂和耐火料一起喷射在被附着的表面上,形成牢固的纤维耐火材料粘结体。这样形成的喷射层具有高强、轻质、隔热、节能等优点。

1.反弹率低

2.热导性小,保温效果好

3.有助于减少高炉、热风炉热损失,延长使用寿命,节约成本

HX high-strength compound insulating fiber gunning mix are developed on the base of general and dry-type spray coating mixes (Patent No. 200610017726.1), improving insulating performance, lowering thermal loss, preventing shell over-heating, increasing warm air temperature. It is with the processed sphere fiber wool with certain strength, the refractories are gunned on the surface with he high-pressure gunning installation process,forming a strong integrate of fiber and refractory. The gunned layer has advantages of high-strength, light weight, insulation, saved energy, etc..

1. Low rebounded elasticity.

2. Low thermal conductivity, excellent heat-retaining properties.

3.Helping to reduce heat loss of blast furnace and hot stove and prolong the service life, showing saved cost

|

项目 Item |

单位 Unit |

XWPT-1 |

XWPT-2 |

||

|

Al2O3 |

% |

42—48 |

38—45 |

||

|

体积密度 Bulk density |

110℃×24h |

g/cm3 |

0.9—1.05 |

1.2±0.1 |

|

|

抗折强度 ≥ Bending strength |

110℃×24h |

M.Pa |

≥0.5 |

≥1.5 |

|

|

耐压强度 ≥ Crushing strength |

110℃×24h |

M.Pa |

≥3.0 |

≥4.8 |

|

|

线变化率 Linear change |

1000℃×3h |

% |

-2.8 |

-3.0 |

|

|

热导系数350±25℃ Thermal conductivity |

W/m.k |

0.2—0.3 |

0.3—0.35 |

||

|

工作温度 Working temperature |

℃ |

1050 |

1100 |

||

|

使用部位 Application area |

热风主管、炉顶 Hot stove main pipe, furnace top |

热风主管、围管等 Hot stove main pipe, bustle pipe |

|||

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定 This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

||||

(6)HX管道喷涂料

HX Tube Spray Coating Mix

采用高强轻质耐火材料,添加多种微粉外加剂,运用先进生产工艺,加工制作的适用于高炉、热风炉各种管道的喷涂料。常用于高炉炉顶煤气导出管及下降管、热风主管、围管及烟道内衬等部位。

产品具有耐高温冲刷和高温下低收缩率、低热导率、抗剥落性、对CO气体具有抗腐蚀性等特点,成功解决了强度与隔热的矛盾,达到了增加管道使用寿命的效果。

The products are one kind of spry coating mix, made of high-strength light-weight refracture with various kinds of micro powders as additives and the advance processes,widely used in various of tubes of blast furnace and hot stove, ordinarily used in gas tube and decline tube at the top of blast furnace, main hot-air tube, packing tube and flue, etc..

The product have the advantages of resistance high-temperature wear, low shrinkage rate at high-temperature, low thermal conductivity, spalling resistance, resistance to CO gas corrosion, solving the problem of strength not in line with insulation, resulting in longer service life.

|

项目 Item |

单位 Unit |

HXGDP-1 耐冲刷喷涂料 (CMG-BF) Spray coating mix resistance to wear |

HXGDP-2 轻质喷涂料 Light weight spray coating mix |

|

|

化学成分 Chem.comp |

Al2O3 |

% |

≥45 |

≥35 |

|

体积密度110℃×24h Bulk density |

g/cm3 |

≥1.9 |

≥1.4 |

|

|

烘干强度110℃×24h Baking strength |

M.Pa |

≥5 |

≥3 |

|

|

烧后强度1300℃×3h After burning strength |

M.Pa |

≥6 |

≥4 |

|

|

使用部位 Application |

高炉上升管、下降管及除尘器内衬 Lifting pipe,down pipe and dust catcher |

热风围管、烟道内衬 Hot-air packing tube, flue |

||

|

备注 Remark |

此参数并非华西产品保证值,指标应根据使用环境在合同中临时约定 This specification is just for reference. The real products will be made tailored to operation conditions and customers’ special requirements. |

|||

粤公网安备 44030702001206号

粤公网安备 44030702001206号